Shocks that occur less frequently could inflict bigger losses and also need to be on companies’ radar. The COVID pandemic is a reminder that outliers may be rare – but they are real possibilities that companies need to consider in their decision making.

Digitalization

Building a Resilient Supply Chain with Smart Solutions

Supply chain disruptions are becoming increasingly common due to global pandemics, trade conflicts or natural disasters. Many businesses are struggling to keep up. How can you build supply chain resilience in such dire times?

Why Supply Chain Resilience is Essential

The COVID-19 pandemic has revealed just how fragile supply chains can be. Companies were facing delays, shortages, and unexpected costs, highlighting the need for a more efficient approach to supply chain management.

These weren’t just pandemic-specific issues. McKinsey identifies four types of disruptions businesses must now prepare for, ranging from trade wars to climate events to global pandemics and even cyberattacks. Some of these are rare instances, but all of them are real. The average company can now expect a major supply chain disruption every 3.7 years.

To survive and thrive, companies must adopt intelligent digital systems that provide flexibility, visibility, and control.

How You Build a More Resilient Supply Chain

In today’s world, digitization is the obvious solution to these challenges. “Supply chain digitization” is more than just a buzz phrase. Data has shown that digitized supply chains and operations can spawn annual efficiency gains of 4.1% and boost revenue by 2.6% a year (source: SupplyChain Magazine).

If you are still early in your digitalization journey, the number of solutions on the market may be overwhelming – so here are some key considerations when reviewing potential digital systems and processes:

1. All-in-One Data Depository

You will need a system that allows you to connect data inputs from multiple sources – whether it be your C-suite offices, manufacturing plants, or R&D facilities – and provide real-time signals. This will lower the amount of time spent searching and compiling data housed in various formats and locations, in turn increasing the amount of time available for analysis and strategy.

2. Integrated Business Network

You will need a system that allows your business suppliers, partners, manufacturers, distributors, and retailers access to this relevant data on a cloud – at any time and in any place. This will enable all key stakeholders within and outside your business to evaluate strategic options with greater pace and make decisions based on real-time data signals.

3. Introduction of ‘Control Towers’

You will need a system that allows you to build ‘control towers’ – i.e. teams who have access to all shipment and inventory data, analytical tools needed to diagnose issues and perform test scenarios, and the authority to resolve problems as and when they occur. When given access to additional artificial intelligence tools, your control towers will allow your business to break down incoming data, highlight critical shifts in supply chain variables, and prescribe the necessary solutions needed to pre-empt or mitigate changes in demand.

Ultimately, you will require a comprehensive solution capable of providing the end-to-end data visibility needed for an agile and efficient supply chain.

Example of a Smart Inventory Management System Boosting a Resilient Supply Chain

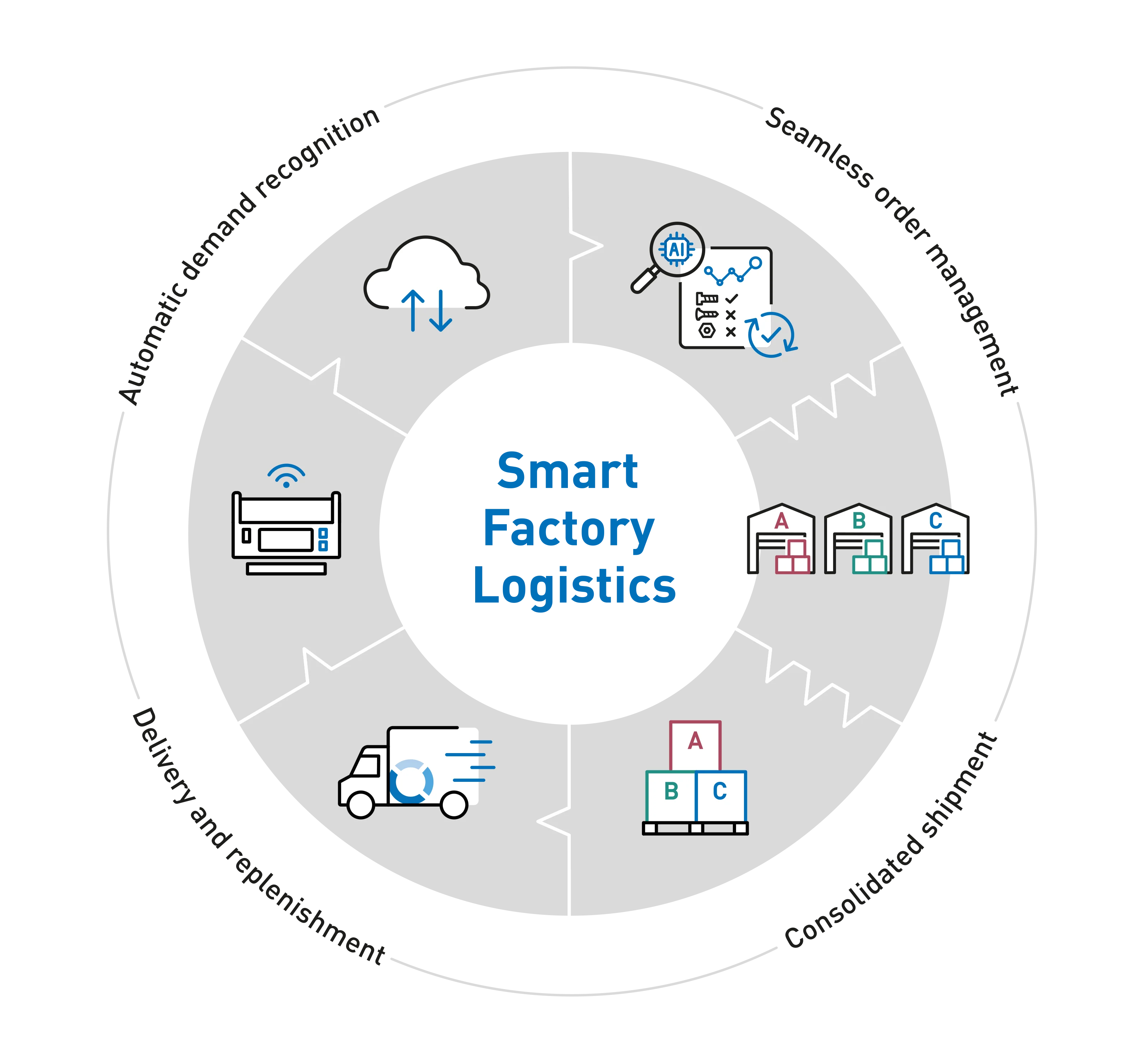

Our Smart Factory Logistics solution helps businesses with effective inventory management – it improves supply chain visibility and reduces inefficiencies by focusing on automation and real-time data tracking. The result is a more agile and cost-effective operation that helps minimize disruptions. Here’s how it works:

- System Set Up: Embedded sensors and smart systems are installed at your production facilities to monitor stock levels and usage in real-time.

- Seamless Order Management: The system automatically forecasts demand, places restock orders, and ensures parts are replenished just in time, minimizing manual intervention and human error.

- Consolidated Delivery: We consolidate orders to reduce your transportation costs and carbon footprint.

- Point-of-Use Replenishment: Parts are delivered directly to their needed location on your production floor – saving time, space, and handling effort.

Benefits of Supply Chain Digitization

This end-to-end service streamlines operations and brings agility to the forefront of your manufacturing process. Companies using Smart Factory Logistics experience:

- Up to 60% reduction in inventory handling costs

- 70% improvement in inventory data accuracy

- 50% reduction in time spent on material issuance

- Greater visibility of material flow and demand signals

In this way, you are better prepared for any future disruptions. Real-time data insights allow you to always be on top of your supply chain – and you can react faster and thus minimize negative impacts when you identify potential issues.

Get More Insights

Supply Chain Resilience White Paper

Don’t wait for the next disruption! Start building a smarter, more resilient supply chain today. Download our free white paper to get started.

Download NowRead More

Supply Chain Management

How to Optimize Your C-Parts Management

All you need to know about C-parts management: Uncover how you can use the total cost of ownership concept (TCO) to improve your supply chain processes and cut costs.

Read On

Bossard Blog

Read more interesting articles about supply chain management, fastening technology and more in our blog.