The Hidden Pain Points in Front End Tools

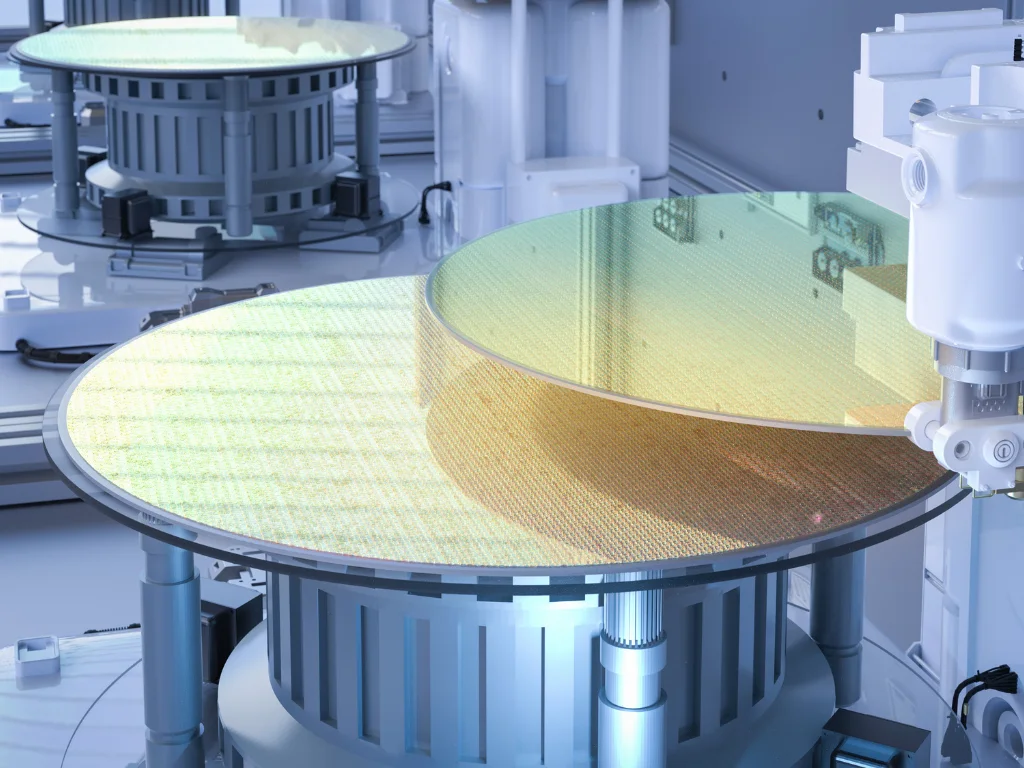

Wafer fabrication tools such as lithography, etching, and chemical vapor deposition systems operate under vacuum and extreme temperature conditions. Fasteners in these environments must resist galling, avoid particle generation, and maintain precise torque values during countless process cycles. Traditional hardware can fail through micro-vibration, corrosion, or material incompatibility, leading to contamination, costly downtime, and yield loss.

Engineers know that the smallest issue in a vacuum interface or chamber mount can cascade into production delays. Replacing contaminated or worn fasteners is not only time-consuming but also expensive, often requiring tool recalibration and cleanroom requalification. These are the challenges Bossard has worked to eliminate through specialized product development and close collaboration with semiconductor OEMs.